About Us

Established in 1996

Jothi Speciality Papers is a pioneer in the production of high-quality, tree-free cotton paper made entirely from pre- and post-consumer cotton textile waste.

The idea was born out of concern for the growing volumes of textile waste generated in industrial hubs like Tirupur, Erode, Salem, and Karur. Witnessing this environmental challenge firsthand, Mr. Mani, along with his wife, founded Jothi Speciality Papers in 1996 with a vision to transform waste into a valuable resource. Anticipating the increasing impact of the fashion industry on textile waste, Mr. Mani dedicated the next three decades to refining operations and building capacity to scale sustainable solutions.

Mr.P Mani

Founder

Ms.M Amutha

Co-Founder

What sets Jothi Speciality Papers apart is its unwavering commitment to sustainability, a no-fuss approach to innovation in circularity, and a deep-rooted dedication to protecting their environment. The company has become a benchmark in zero-waste management and continues to demonstrate how responsible business practices can drive both environmental and economic success.

Today, Jothi Speciality Papers is not only a pillar of its local community but also a leader in commercialising circular systems and textile waste management on a broader scale with the introduction of their brand ReCoRev – Tree Free Paper co-created by Urvara Pty Ltd.

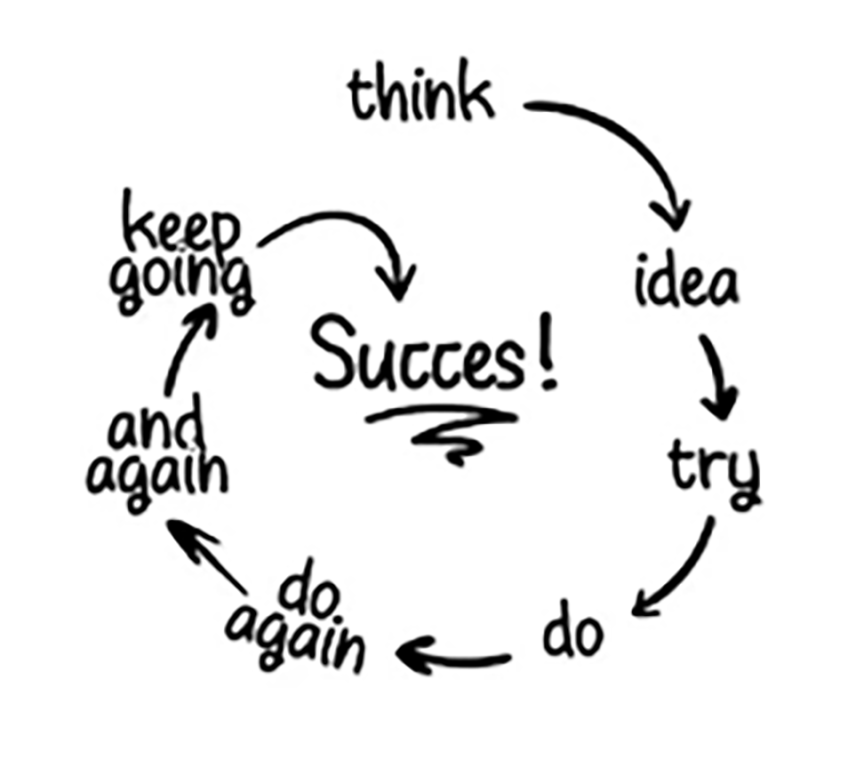

Our Process

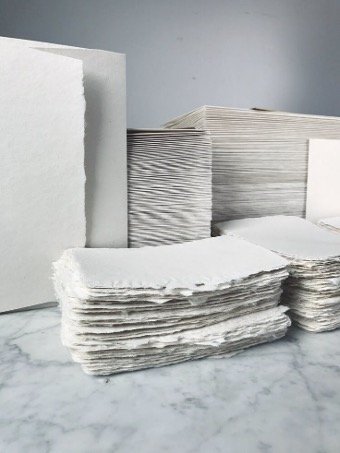

The feedstock of cotton rags are colour sorted and granulised through the shredding machine. The shredded fabric goes through a series of wetting and fermentation process to produce pure cotton cellulose.

The cotton cellulose pulp is then fed through a conveyor system and pressed through rollers forming sheets of paper, the paper thickness is maintained by controlling the space between the rollers.

Finished sheets are laid one on top of the other until much of the moisture content is removed.

Each sheet of paper is hung to dry under a shaded canopy and is dried completely only the sun’s heat.

The paper once completely dried is sorted based on size and then goes through a calendaring process, quality control, edge cutting and finally packing.

The entire process is completely free of toxic chemicals, the fermentation process is supported by a bespoke Zero Liquid Discharge system — ensuring zero wastewater and sustainable water usage.

The paper is dried naturally under the sun, eliminating the need for mechanical heating, and significantly reducing carbon emissions. All of this takes place in a facility powered entirely by solar energy, making JSP’s paper production energy-efficient, clean, and circular.

Let us know how we can help you ?

Send a Message

Address

Jothi speciality papers 3/224A, Thulukankadu, Kaliyanoor Rd, Pallipalayam, Tamil Nadu – 638008

Phone

+91 95974 00722

jothipapers@gmail.com